-

Products and Systems

Products and Systems

Vinidex manufacturers and supplies a broad range of products & systems to suit a range of applications.

-

Solutions

Solutions

Vinidex’s products and systems are versatile and can be used in a variety of markets and applications.

- Resources

-

How to Choose the Right High Density Polyethylene Pipe for Your Project?

Choosing the right high density polyethylene pipe (HDPE) for your project is crucial. The global demand for HDPE pipes is projected to reach USD 28 billion by 2025, as per industry reports. This demand stems from their versatility, durability, and resistance to corrosion. HDPE pipes are ideal for water supply, sewage, and gas distribution systems.

Consider your project's specific needs when selecting an HDPE pipe. Factors like pressure ratings, pipe diameter, and intended use play an essential role. Experts suggest looking into the installation environment. For instance, pipes used in agricultural settings face different challenges than those used in urban construction.

However, not all projects require the same specifications. Over-engineering or underestimating pipe requirements can pose future risks. A well-researched choice can save costs in repairs and replacements later. Understanding these aspects helps ensure the right HDPE pipe is chosen, leading to a successful project outcome.

Factors to Consider When Selecting High Density Polyethylene Pipes

When selecting high density polyethylene (HDPE) pipes, consider various critical factors. These pipes offer durability and resistance to stress, making them suitable for many applications. According to industry reports, HDPE pipes can withstand pressures of up to 1600 psi, a significant feature for high-demand projects.

Evaluate the pipe's diameter carefully. The size impacts flow rates and pressure drops. A larger diameter allows for higher flow rates but may increase costs. Additionally, consider the pipe's intended use, such as water supply or gas distribution. Different applications may require specific standards and certifications.

Also, take into account the environmental conditions. For instance, factors like soil type and temperature affect the pipe's performance. Reports suggest that HDPE pipes can expand or contract by 0.2% for every 10°F change. This characteristic requires careful planning in installation. Reflect on the long-term maintenance needs as well. While HDPE pipes are generally low-maintenance, installation errors can lead to costly repairs down the line.

High Density Polyethylene Pipe Selection Factors

Applications of High Density Polyethylene Pipes in Various Industries

High density polyethylene (HDPE) pipes are essential in many industries. They are widely used in water and wastewater management. Their durability makes them suitable for tough environments. For example, HDPE pipes offer a long service life in harsh weather. Industries that require reliable piping often prefer this material.

Another application is in agricultural irrigation. Farmers use HDPE pipes for drip and sprinkler systems. These pipes help conserve water and improve crop yields. They resist corrosion, which is crucial for soil health. Additionally, construction projects benefit from HDPE for drainage systems. However, installation can sometimes be tricky. Careful planning and proper techniques are necessary for optimal results.

In the gas industry, safety is paramount. HDPE pipes are increasingly used for gas distribution. They provide a lightweight option that reduces the risk of leaks. Still, operators need to be mindful of proper installation practices. Ensuring joint integrity is critical for safety. Overall, while HDPE pipes present numerous advantages, the choice requires careful consideration.

Understanding Different Grades and Specifications of HDPE Pipes

When selecting high-density polyethylene (HDPE) pipes, understanding their grades is crucial. HDPE pipes come in various grades, which impact their durability and intended use. The most common grading systems are PE63, PE80, and PE100. Each grade represents different pressure ratings and strength levels. For example, PE100 pipes are often favored for high-pressure applications due to their superior strength.

Consider specific project requirements. If your project involves water transport, PE100 is generally recommended. However, if cost is a major concern, PE80 may suffice for low-pressure systems. It's essential to assess the environmental conditions as well. Factors like temperature and potential chemical exposure can influence the pipe's longevity and performance. HDPE's resistance to corrosion is beneficial, but not absolute.

As you evaluate options, be aware of your local standards and specifications. Each region may have different regulations for HDPE pipes. Ignoring local guidelines can lead to challenges in approval and usage. It's a learning process that requires attention to detail and constant review of the materials available. Mistakes in this choosing phase can lead to costly repairs later.

Key Advantages of High Density Polyethylene Pipe Systems

High density polyethylene (HDPE) pipes are gaining popularity in many projects. They offer several key advantages that make them a go-to choice for engineers and builders. One significant benefit is their resistance to corrosion. Unlike metal pipes, HDPE pipes do not rust. This means fewer maintenance costs over time. They also resist chemical degradation, making them suitable for various environments.

Another advantage is their flexibility. HDPE pipes can bend without breaking, allowing for easier installation in tight spaces. This flexibility can lead to fewer joints and less risk of leaks. It’s important to note that while they are durable, exposure to UV light can degrade HDPE over time. Proper protective measures can help mitigate this issue.

Additionally, these pipes are lightweight. This reduces transportation costs and makes handling easier on-site. However, the lightweight nature can also lead to concerns during heavy rain or flooding. Evaluating site conditions and proper anchoring is essential. Not every project will benefit from HDPE. Assessing the specific needs is crucial for optimal performance.

Best Practices for Installation and Maintenance of HDPE Pipes

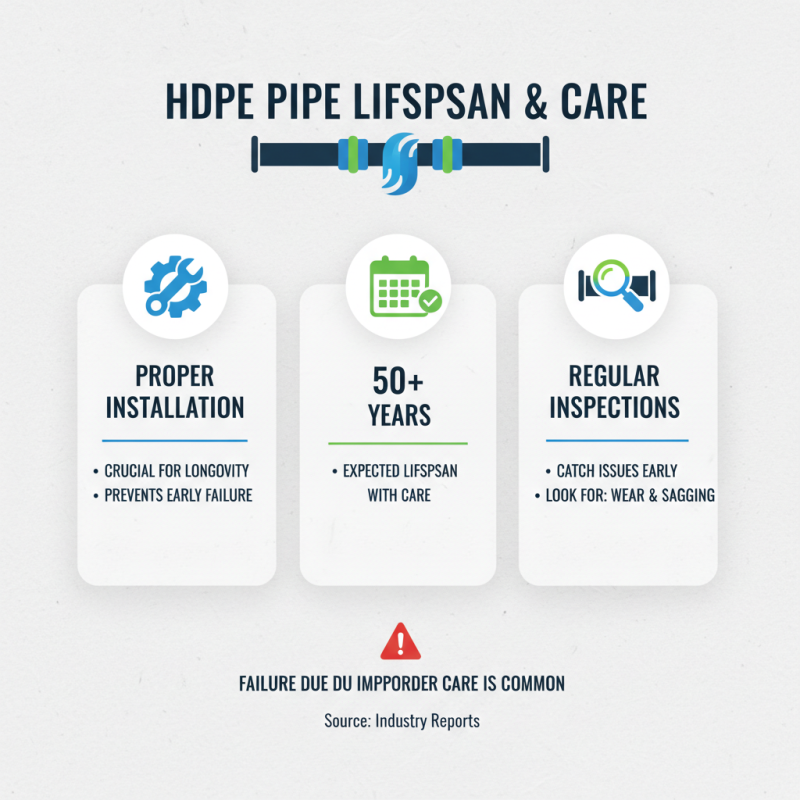

When dealing with high-density polyethylene (HDPE) pipes, proper installation and maintenance are crucial. According to industry reports, well-installed HDPE can last over 50 years. However, many projects fall short due to improper care. Regular inspections can catch issues early. Look for signs of wear or sagging.

Tips: Always verify the pipe's alignment. Misalignment can cause stress and lead to future failures.

Another consideration is temperature control. HDPE pipes can expand and contract significantly with temperature changes. According to a study by the Plastics Pipe Institute, thermal expansion could be as much as 1 inch per 100 feet at a temperature change of 100°F. Keep this in mind during installation to avoid possible breaks.

Tips: Utilize supports to minimize movement. They help maintain structural integrity and extend the pipe's lifespan.

Maintenance work should include checking the connections and fittings regularly. Loose connections may lead to leaks. A simple fix can save money and time in the long run. Inadequate maintenance practices can lead to costly repairs and project delays. Stay proactive, and ensure the longevity of your HDPE pipes.

Related Posts

-

2025 Top Insights on HDPE Plastic Pipe: Benefits, Applications, and Trends

-

2025 How to Choose the Best HDPE Sewer Pipe for Your Project

-

Understanding the Benefits and Applications of HDPE Plastic Pipe in Modern Infrastructure

-

Understanding the Advantages of High Density Polyethylene Pipe in Modern Infrastructure Solutions

-

2025's Top 5 HDPE Plastic Pipe Innovations for Efficient Water Management

-

Why Choose HDPE Water Pipe for Your Next Plumbing Project?